Roll over or click image to zoom in

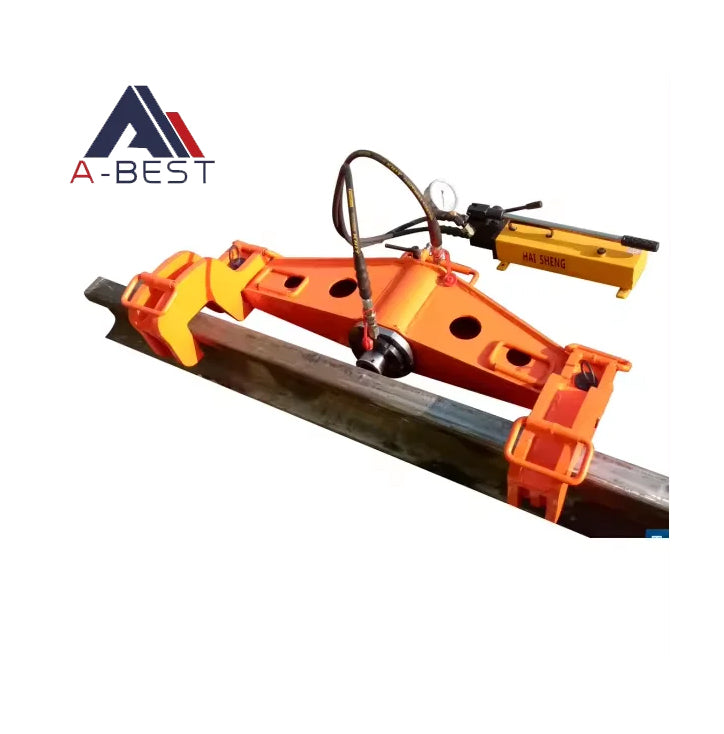

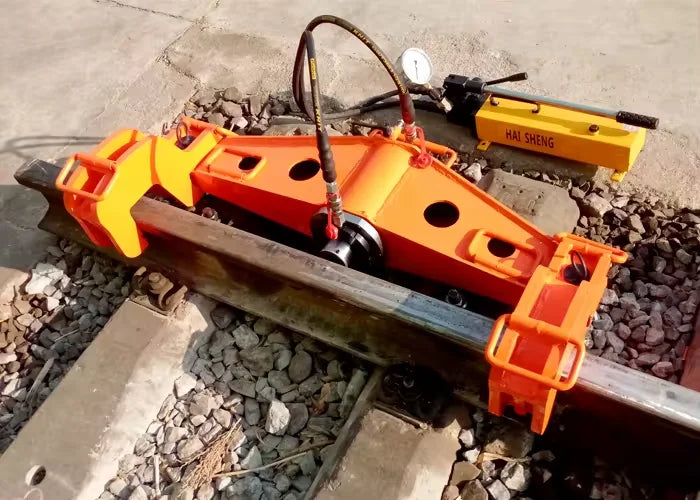

YZG-550 Hydraulic Rail Bending Machine Horizontal Guide Rail Bender Tool Rail Bender

customers are viewing this product

Product Description

Rail Bender

YZG-550 double-hook rail bender is a special manual hydraulic equipment for 43kg/m——75kg/m rail bending operation. The machine is made of special steel welded with reliable performance, compact structure, light weight and convenient dismounting.

Specification

|

Product

|

hydraulic rail bender

|

|

Model

|

YZD-550

|

|

Material

|

Steel

|

|

Dimensions (L x W x H) (mm)

|

Customer's Drawing

|

|

Product name

|

rail bender

|

|

Usage

|

railway maintenance machine

|

|

Certificate

|

CE

|

|

Quality Control

|

Inspection 100%

|

|

bending force

|

550 KN

|

|

Work pressure

|

57 MPa

|

|

piston working stroke

|

120mm

|

|

no-load efficiency

|

1.5mm/time

|

|

Selling Units

|

Single item

|

|

Single package size

|

115X70X40 cm

|

|

Single gross weight

|

124.000 kg

|

Why Choose Us

ZHONGSHENG RUIDA offers proven tools and machines for the professional execution of work on railway tracks. The products work efficiently, precisely. Special equipment ensures more safety, availability and comfort during operation. ZHONGSHENG RUIDA develops and produces tools and machines in track construction, track maintenance and unique special tools for thermite welding processes. We are constantly working on the improvement and further development of our tools and machines, for a long service life of rails.

Company Profile

Certifications

Customer Photos

Packing & Delivery

1.Are you a trading company or manufacturer? We are manufacturer, major in portable rail maintenance equipment and measuring instruments for many years. Keeping promise, first-class service, we won many old customers’ trust and satisfaction. 2.How do you ensure the quality of products? We operate a quality management system that complies with ISO9001 certification standards, certified by CE, CRCC. We accept third-party inspection to provide you with the best guarantee. 3.Can you accept OEM? Any kind and colors can be provided according to your requirements. Customers logo is OK to print on product. 4.How about your lead time? Usually 15-25 days. Our spare parts and finished products are available in minimum stock to meet the immediate delivery of small batch orders. 5.What service you can provide? Professional manual, and videos on machine failure analysis, repair, and spare-parts replacement.